Hello, everybody

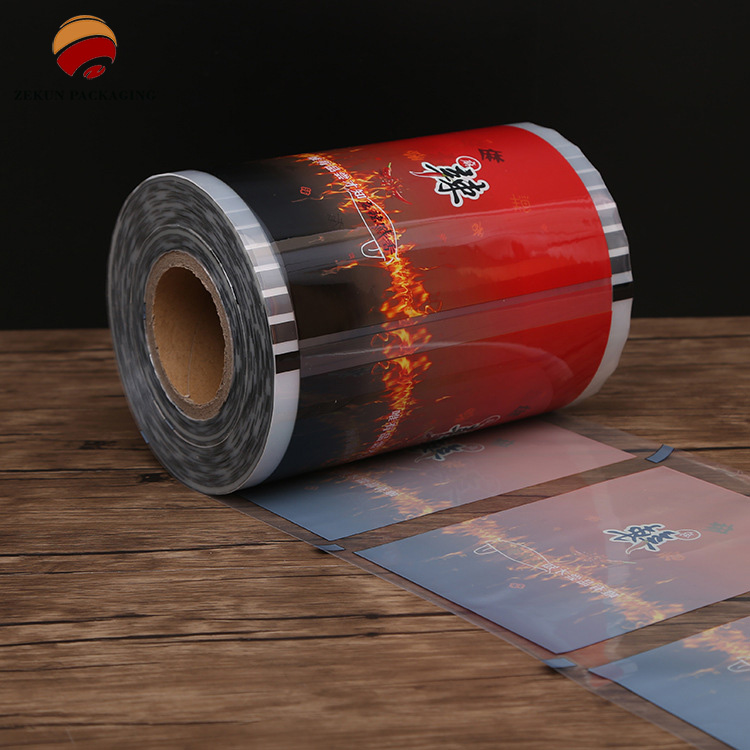

Visible high quality packaging quality

I am Zekun

If you get the COVID-19 vaccine, you won’t get infected?

Some people may think that if you get the COVID-19 vaccine, you won’t get infected, but that’s not true. After you get the vaccine, you can only reduce the risk of infection.

Zhong Nanshan said: “In addition to vaccine prevention, the most effective way to treat the new crown is multiple monoclonal antibodies, but only now has it been discovered that some of the antibodies have failed against the new crown virus strain. So we have been facing challenge one by one. The mutation of the virus strains currently encountered will bring great challenges to our prevention. It will make the vaccine ineffective and may also reduce the effect of antibody treatment.”

At present, in addition to vaccination prevention, it is essential to prepare masks and other prevention and control materials. Roll film packaging provides clean and hygienic masks for these prevention and control materials.

Editor Zekun will tell you some basic knowledge about automatic packaging roll film as below:

lAdvantages of automatic packaging roll film:

Roll film packaging bags are used in automatic packaging machinery. When manufacturing packaging film rolls, packaging manufacturers only need to perform printing operations, without any edge sealing work, and are supplied to buyers in rolls. Due to the transportation of rolls, the transportation is reduced. cost. Larger brand companies or companies that require the same kind of packaging bags for a long time have chosen to directly purchase packaging film and use automatic packaging machines to make them into bags. In fact, the process of packaging film and packaging bags is the difference in bag making processes. Therefore, the emergence of roll film simplifies the entire process of plastic packaging into three major steps: printing-transportation-packaging, because roll film packaging is fully electric and integrated, and the machine is self-packed, which can save materials when using automatic packaging roll film. , Save labor, save time, is the best choice for small package products.

lThe usage of automatic packaging film:

Application scope of automatic packaging film: hardware screws, electrical parts, snack foods, stationery, small toy parts, cosmetics, agricultural products, powder packaging, liquid packaging, etc. Features: Good heat sealability, low material cost, automatic packaging can save manual packaging costs.

According to the usage, it can be divided into heat sealing film and laminated film:

1. Heat sealing film:

Single layer heat sealing film, mainly BOPP heat sealing film, CPP film, used for hardware screws, electrical parts and other independent packaging.In daily life, milk tea, porridge and other small shop site packaging sealing machine, it is used to seal the film is the film, the most common film packaging is bottle packaging, and generally use POF film, such as part of Coke, mineral water and so on.

2.laminated roll film:

The structure of the laminated roll film is based on the characteristics of the packaging product. There are three and four layers in generally. The outer layer material is polyester, nylon, stretched polypropylene, paper, etc. The middle layer material is aluminum foil, aluminum, polyester, nylon, etc. The inner layer material is cast polypropylene, polyethylene, etc. Different laminated film structures are usually formulated according to the three-layer materials. The laminated roll film is suitable for vacuum packaging or general packaging of food, electronic products, chemicals, medicine, tea, precision instruments and cutting-edge defense products.

lMaterial of automatic packaging laminated film:

1) PET/PE laminated film:

The material of OPET/LDPE composite film is polyethylene terephthalate and high-pressure polyethylene. It is usually abbreviated as PET/PE laminated bag. It has the characteristics of high transparency and good oxygen barrier. It can be used as a mask packaging film, and Since this laminated film has good heat and cold resistance, it can also be used as a packaging bag for quick-frozen food and retort food.

2) BOPP/CPP laminated roll film:

The materials of BOPP/CPP laminated film are biaxially oriented polypropylene and unstretched polypropylene, which are customarily called OPP/CPP laminated film bags. Among all laminated films, it has relatively high transparency. Compared with single-film plastic bags, the cost is higher than single-film plastic bags at the same thickness, but the hand feel is better than single-film bags; and because of the good moisture barrier properties of this kind of film, it is used in food, mainly for packaging Dry foods and fast foods, such as biscuits, instant noodles, etc. The disadvantage is that it has poor high temperature and cold resistance, and it is not suitable for packaging refrigerated and high-temperature sterilized food.

3) OPP/PE laminated roll film:

The BOPP/LDPE laminated film is laminated of two-way stretched polypropylene and high-pressure polyethylene laminated film bags, generally abbreviated as OPP/PE laminated film, which is the largest variety of plastic films, with good flexibility, high elongation, and hardness Low-roll film, its oil resistance effect is also good, so cooked food and some oil products are also packaged in this bag.

lSterilization method of automatic packaging roll film

The air contains a lot of microorganisms and bacteria that are invisible to the naked eye. If the sterilization effect of the packaged food container is not obvious or the protection is improper, it may cause secondary pollution, and human consumption of contaminated food will cause harm to the body. For people’s health and safety, we usually sterilize the roll film. So how can sterilization be truly effective to protect the safety of food? For automatic packaging roll film sterilization, we adopt two special sterilization methods:

1) Ozone sterilization:

Ozone is a strong oxidant, and its sterilization process is a biochemical oxidation reaction. Ozone first acts on the cell membrane, causing damage to the components of the cell membrane, leading to metabolic disorders. Ozone continues to penetrate the cell membrane to destroy lipoproteins and lipopolysaccharides in the cell membrane, changing the permeability of the cell and leading to cell death.

Using ozone sterilization to sterilize production equipment and products can improve the quality and grade of food packaging roll films.

2) UV sterilization:

Ultraviolet sterilization is the use of ultraviolet wavelengths to destroy the molecular structure of DNA or RNA in bacteria and viruses, forming growth cell death and regenerative cell death, to achieve the effect of sterilization and disinfection.

Taken together, the penetration ability of ultraviolet rays is relatively poor, but the cost of the two methods is not much different, so Ze Kun editor here suggests that you should use ozone sterilization for food packaging roll film, the purpose is to increase the sterilization area So as to achieve a better sterilization effect.

warm prompt:

Even if the vaccine is developed we cannot treat STH lightly, after all, according to the current research results, the vaccine is not foolproof, antibody does not always exist, immune duration is only 6 months, although we believe that the vaccine is safe and effective, but after vaccinated against new crown, or require you to maintain personal protective measures,This includes habits such as wearing masks, maintaining social distance and washing your hands frequently, since vaccines aren’t 100 percent protective.

No comment yet, add your voice below!