The role of packaging in candy and chocolate

1. Protect the product’s due luster, fragrance, shape, and extend shelf life

It is very important for candies and chocolate to maintain their proper appearance within a certain period of time. For example, fruit hard candy should have good transparency and corresponding fruit aroma, and the surface of chocolate should have good brightness and cocoa aroma. These qualities are maintained very well. To a large extent depends on the packaging form, packaging material and packaging effectiveness.

All kinds of candies contain different amounts of reducing sugar. This reducing sugar has the property of easily absorbing moisture in the air. Therefore, the candies will absorb moisture to varying degrees in a humid environment. Once the candies absorb moisture After that, it will become sticky (fashang in technical terms) and lose its due transparency.

Chocolate products are heat-sensitive foods and also high-fat products. Therefore, when the indoor temperature exceeds 25°C and reaches 30°C, the product begins to soften. This phenomenon is that some of the low-melting fat contained in the chocolate begins to melt, and the melted fat will migrate to the surface of the chocolate. The migrated fat will not only make the chocolate become It is soft and will make the surface dull, and severely make the product surface blooming and white; in addition, in a humid environment, the sugar contained in the chocolate will also absorb moisture and deliquescence, and the deliquescent sugar will cause the product to become sticky.

2. Prevent microbial and dust pollution, improve product hygiene and safety

Chocolate products are high-protein foods. It is especially important to prevent microbial contamination of praline fillings or brownie products, because protein and the nutrients in chocolate are excellent microbial culture media. If these products are contaminated by bacteria, they should be stored in storage. In the process, it will accelerate the speed of product worms and deterioration, resulting in the loss of commodity value. Therefore, tight packaging can avoid microbial contamination and ensure product hygiene and safety.

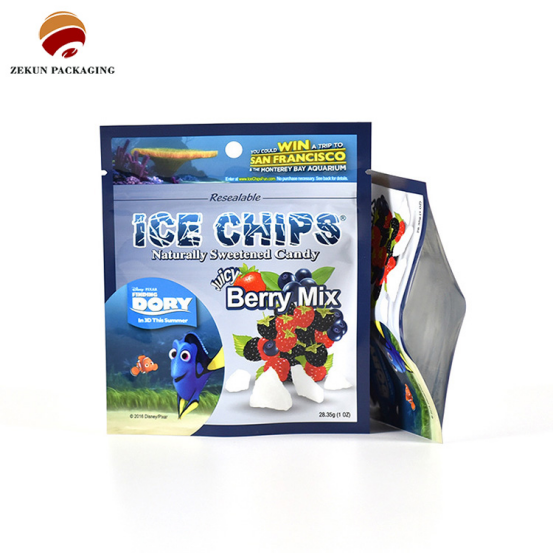

3. Exquisite product packaging can increase consumers’ desire to buy and the value of goods

Commodity quality, price, and packaging are the three main factors in market commodity competition. And the packaging design is an important one in the road to the market. Because of the distinctive product packaging design, it will give people a strong visual effect on the shelf and increase consumers’ desire to buy. Therefore, good food must have the three main factors of product quality, price, and packaging, so as to increase the value of the product. From the above points, it can be seen that packaging plays an important role in the quality, hygiene, and price life of candy and chocolate products. Good products must have exquisite and beautiful packaging.

Candy packaging

The traditional candy packaging is wrapped in wax paper. Later, it is gradually changed to cellophane wrapping. Now it is mostly wrapped in plastic film. Plastic film has good moisture resistance, high tensile strength, low price, abundant sources, diverse varieties, good mechanical adaptability, and is suitable for high-speed automated packaging. Commonly used films include HDPE, OPP, BOPP and aluminum foil/PE.

Confectionery packaging has various wrapping forms such as twisted, folded and seamed. Seam wrapping, also known as pillow wrapping, is an advanced candy packaging technology developed in recent years. It is characterized by heat-sealing, good air-tightness, and moisture-proof and moisture-proof for a long time. , Preserving fragrance, its shelf life is greatly improved, and the packaging form is novel, which can save packaging materials.

General candy packaging needs to be printed and decorated, supplemented by exquisite patterns, to enhance the commodity value and attractiveness of the candy. Traditional candy printing is on the reverse side of the wrapping paper. When there is no inner wrapping paper on the candy block or the wrapping paper is skewed and loose, the printing ink will directly contact the candy and cause the ink and residual solvent to contaminate the candy. Therefore, this printing method is not acceptable. Taken. According to food hygiene requirements, after printing, packaging materials are coated with a layer of polyethylene on the printing surface to ensure that the candy packaging is non-toxic, hygienic and the printing decoration is exquisite and bright. The packaging film made by this method can be used on an automatic packaging machine, and can be heat-sealed, moisture-proof and gas-barrier, so it can prolong the shelf life of the candy.

Candies can be packaged in simple packaging, bag packaging, box packaging, metal cans, plastic cans, and paper-plastic combination cans.

Chocolate packaging

1.Basic characteristics of chocolate

Chocolate is made of cocoa products (cocoa mass, cocoa powder, cocoa butter), sugar, dairy products, spices and surfactants as basic raw materials, and undergoes scientific processing such as mixing, fine grinding, refining, temperature adjustment, and molding. , Has a unique color, aroma, taste and fine texture, exquisite, preservation-resistant, high-calorie sweet and solid food.

2. Chocolate requirements for packaging

Chocolate is made from raw materials such as cocoa liquor, cocoa powder, cocoa butter, white sugar, dairy products and food additives, which are processed through processes such as mixing, grinding, scouring, tempering, casting, and freezing. The dispersing system of chocolate uses fats and oils as the dispersing medium, all solid components are dispersed between the fats and oils, and the continuous phase of the fats and oils becomes the skeleton of the physique. The main component of chocolate, cocoa butter, has a melting point of about 33°C. Therefore, chocolate will gradually soften when the temperature reaches 28°C, and gradually melt into a slurry above 35°C. The surface quality of chocolate is also greatly affected by ambient temperature and humidity. When the temperature gradually rises from 25°C to above 30°C, the gloss of the chocolate surface begins to dim and disappear, or when the relative humidity is quite high, the gloss of the chocolate surface will also be dim. And disappear. At the same time, if chocolate is packaged or stored improperly, there will be phenomena such as blooming, whitening, oil leakage and insects. In addition, chocolate also has the characteristics of being easy to absorb the odor of other items, some chocolate products will also have a scent, and the shelf life is not synchronized. Therefore, chocolate has relatively high requirements for packaging. It not only requires the packaging to have good basic properties such as water and gas resistance, temperature and melting resistance, light protection, rancidity resistance, dialysis resistance, mildew resistance, insect resistance, and pollution prevention, and it can also be used for a long time. Maintain the color, aroma, taste and shape of chocolate candies.In addition, with the needs of market competition, packaging requires unique forms of expression (including materials, shapes and designs, etc.), rich and colorful content (showing product form, features, and connotation, etc.) and value-added functions to promote products. Sales and increase the added value of products.

3. Commonly used chocolate packaging materials

(1) Paper products. Paper product packaging is a world-recognized non-polluting and environmentally friendly material, but due to its own characteristics, it is generally used for outer packaging, display packaging, display packaging and transportation packaging. Chocolate paper packaging involves coated paper, white cardboard, grayboard, boxboard and corrugated paper. The proportion of high value-added functional papers such as water resistance, oil resistance, acid resistance, deodorization, and wafer paper is gradually increasing.

(2) Tin foil packaging. This is a type of traditional packaging material. Because of its good barrier properties and ductility, it has always occupied a place in the current chocolate packaging. However, it is affected by factors such as production technology, production efficiency, application limitations, and price, and is affected by packaging such as plastics. Great impact.

(3) Plastic flexible packaging. Plastic packaging has gradually become one of the most important packaging materials for chocolate due to its rich functions and diverse display power. With the maturity of technology, cold-seal soft bags have gradually become the most important part of chocolate due to their high packaging speed, low odor, no pollution, easy tearing, etc., and can avoid the impact of high temperature during the chocolate packaging process. Packaging Materials.

(4) Composite materials. Due to the composite characteristics of multiple materials and obvious protective display capabilities, composite materials are easy to obtain materials, simple to process, strong composite layers, and low consumption, and gradually become a commonly used packaging material in chocolate and candies. Most of the composite materials are based on flexible packaging. Currently, commonly used materials include paper-plastic composite, aluminum-plastic composite, and paper-aluminum composite.

(5) Container packaging. Container packaging is also one of the most common packaging methods in chocolate packaging. It mainly has the advantages of excellent protective performance, sophisticated production, unique display effect and reusability. At present, the common container packaging on the market is nothing more than plastic (injection molding, blow molding, blister molding), metal (tinplate cans, aluminum cans), glass and paper (mounted boxes) four categories, in order to pursue the differentiation of product display, Containers such as leather boxes, wooden boxes and composite materials that do not often contain food are also appearing on the market. In addition, ceramic materials can fully express culture and art, and there have been cases in the market that use ceramics to make high-end chocolate packaging containers.

No comment yet, add your voice below!