Everyone is relatively familiar with aluminum foil packaging bags, but they don’t know much about aluminum-plated bags, and they feel indistinguishable. So, what is aluminum-plated packaging bags? What is the difference with aluminum foil packaging bags?

According to Hunan Zekun Packaging, aluminum-plated bags are a kind of aluminum foil bags. Aluminum foil bags can be divided into pure aluminum bags and aluminum-plated bags. The appearance of aluminum-plated bags is opaque, silver-white, and has anti-gloss. It has good barrier properties, heat sealing properties, shading properties, high temperature resistance, low temperature resistance, oil resistance, fragrance retention; non-toxic and tasteless; softness and other characteristics. It has a certain degree of light resistance, and it can still transmit a certain amount of light compared with aluminum foil bags. The aluminum-plated bag has a certain degree of opacity and good light reflection performance, so the printing effect of the bag is better, the color is fuller, and the gloss is better. Compared with aluminum foil bags, bags are less prone to wrinkles.

The aluminum-plated bag adopts a four-layer structure with good toughness, high strength, and good water and oxygen barrier functions. The aluminum-plated bag mainly has the advantages of anti-static; vacuum-proof; light and oxygen; waterproof and moisture-proof; anti-volatile; high tensile strength; high-grade and exquisite packaging. The aluminum-plated bag can be used for moisture-proof, light-proof and vacuum packaging of food, pharmaceutical raw materials, biological chemicals, chemical raw materials, pharmaceutical intermediates, and lithium iron phosphate cathode materials.

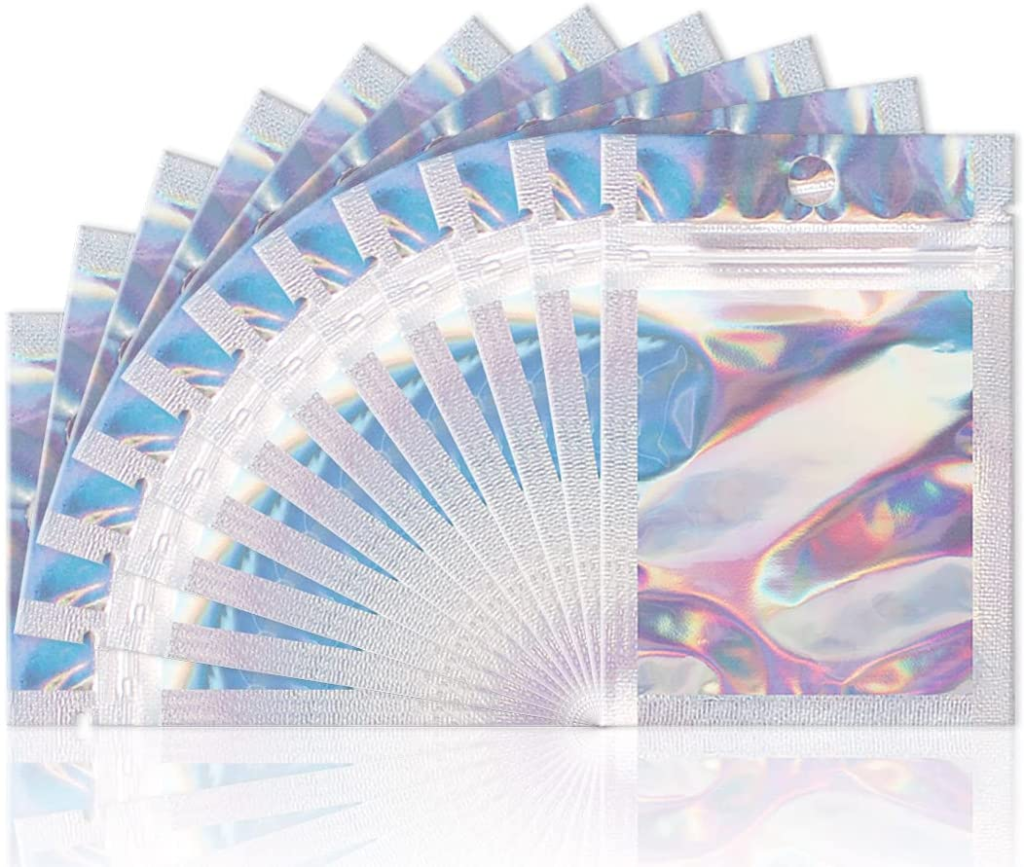

Colored aluminum-plated bags are currently very popular gift packaging materials in the world. The outer layer is a color aluminum-plated film. The film adopts high-vacuum evaporation technology, has bright metallic luster, excellent gas and light barrier properties, and good moisture resistance. , Heat resistance, puncture resistance; excellent adaptability to printing and lamination. The inner transparent PE film has good heat sealability, which can ensure the firmness of the sealing edge. Generally, the color aluminized bag is in the bag The mouth has self-adhesive strips or easy-to-tear strips to facilitate packaging. The aluminum-plated bags are of high quality and bright in color. They are widely used in the packaging of various gifts, handicrafts and other industries that require environmental protection.

Aluminum foil bag packaging usually refers to aluminum-plastic composite vacuum packaging bags. This type of product is suitable for moisture-proof, light-proof and vacuum packaging of large-scale precision machinery, chemical raw materials, and pharmaceutical intermediates. It mostly adopts three-layer or four-layer structure, which has good water and oxygen barrier functions. Unrestricted, you can customize packaging bags of different specifications and styles, and can be made into flat bags, three-dimensional bags, organ bags, zipper bags and other styles. Products need to be tested by GB and ASTM standards. Products meet environmental protection requirements (third-party test reports can be provided). Products meet the most stringent environmental protection standards for packaging materials in the European Union and North America.

Aluminum foil bags are divided into pure aluminum bags and aluminum-plated bags. How to distinguish aluminum-plated bags and pure aluminum bags in daily life? There are a few points to summarize:

1. In terms of material, the pure aluminum bag is pure aluminum with high purity and is a soft material; the aluminum-plated bag is mixed with composite materials, which is a brittle material.

2. In terms of cost, the price of pure aluminum bags is higher than that of aluminized bags.

3. In terms of performance, pure aluminum bags have better moisture-proof and cooling effects than aluminum-plated bags, pure aluminum bags are completely protected from light, and aluminum-plated bags have a shading effect.

4. In terms of use, pure aluminum bags are more suitable for vacuuming, such as cooked food, meat and other products, while aluminum-plated bags are suitable for tea, powder, electronic parts, etc.

5. The inside of the bag is facing the light or the sun, the light that can be seen through the bag is the aluminum foil, the invisible is the pure aluminum foil

Today, the editor of Zekun will share this with you. For more information, please pay attention to our website:https://www.zekunpackaging.net/ or https://www.zekunpackaging.com/

No comment yet, add your voice below!